Are you struggling to manage your supply chain smoothly? Learn how top companies follow five key steps to boost efficiency and stay ahead in the market. Supply Chain Management is crucial for the success of any business involved in the production and distribution of goods. Whether you’re a business owner trying to streamline operations, a student exploring a career in logistics, or simply curious about how goods travel across the globe, understanding the five basic steps of supply chain management can give you a clear edge.

In this article, we’ll break down the five basic steps of supply chain management and show how mastering them can lead to smoother operations, happier customers, and long-term success.

What is Supply Chain Management?

Supply Chain Management is a system that manages all the steps involved in producing a product or service and delivering it to the customer. It includes sourcing raw materials, manufacturing, storing, transporting, and delivering the final product. The main goal of Supply Chain Management is to deliver the right product to the right place at the right time, with minimal cost. Through efficient supply chain management, companies improve their operations, increase customer satisfaction, and boost profits. In today’s competitive world, effective Supply Chain Management is essential for the success of any business.

Why is Supply Chain Management Important?

Supply chain management plays a crucial role in helping you achieve key business goals. When you have control over each link in the chain, you’re able to enhance product quality, minimise production issues, and maintain a consistent brand reputation. A well-managed supply chain reduces unnecessary costs, cuts down on waste, and helps avoid delays, all of which contribute directly to higher profitability and smoother operations. Companies that invest in strong supply chain strategies are better positioned to compete in fast-moving markets. These companies can respond quickly to changes, anticipate potential disruptions, and stay compliant with regulations. This means products are more likely to arrive on time, meet quality expectations, and build lasting customer trust.

Today’s businesses are also expected to operate responsibly. With the growing emphasis on environmental sustainability, supply chain management gives you the tools to make greener choices. From energy-efficient logistics to reducing packaging waste, a sustainable supply chain not only protects the planet but also shows customers that your business cares about the future.

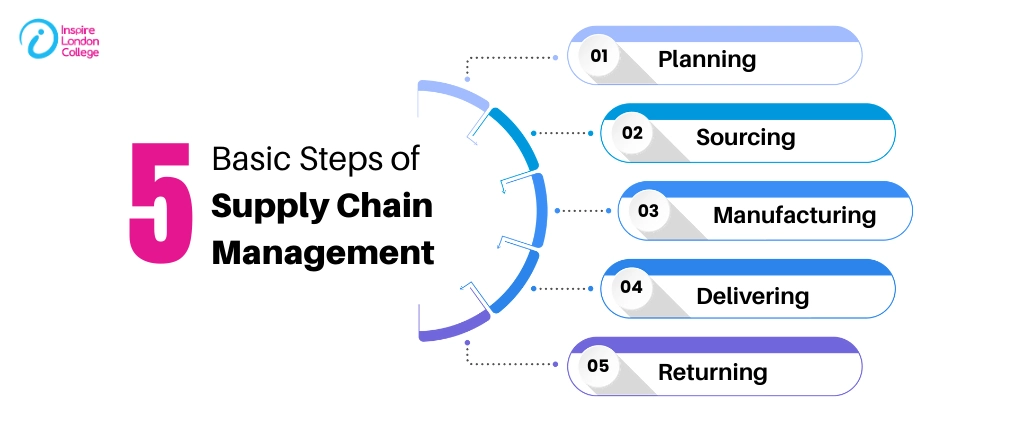

5 Basic Steps of Supply Chain Management

What helps the supply chain run smoothly from start to finish? First, you need to get familiar with the five essential steps. These five core steps work together to move a product from concept to customer efficiently, accurately, and profitably. Let’s break down each stage to see how it contributes to a seamless and successful supply chain:

1. Planning

Have you ever wondered how companies know exactly what, when, and how much to produce? It’s not guesswork; it’s smart planning. Behind every smooth-running business is a strategic approach that aligns supply with customer demand.

Planning is the first and most important step in supply chain management. It involves forecasting demand, identifying resources, and developing a strategy to meet customer needs effectively and efficiently. Accurate planning is essential for a successful supply chain. Without proper planning, businesses may produce too much or too little, leading to waste or stock shortages. This step’s key tasks include forecasting customer demand, planning the capacity of resources, managing inventory levels, assessing risks, and creating a budget. Good planning helps make sure that the right products are available at the right time and place. Planning also helps businesses reduce waste, control costs, and keep customers satisfied. Without a strong planning process, the rest of the supply chain can become inefficient and unreliable.

2. Sourcing

Do you know one weak link in your supplier chain, like a sudden dropout or low-quality delivery, can disrupt your entire operation? That’s why sourcing isn’t just about buying materials; it’s about building strong, strategic partnerships that keep your business running smoothly.

In the sourcing stage, businesses focus on selecting the best suppliers to provide the raw materials, products, or services needed for production. Companies create contracts and agreements, manage the buying process, and regularly check supplier performance to ensure everything runs smoothly.

Selecting reliable suppliers reduces risks such as delays, poor-quality materials, or high costs. Additionally, sourcing strategies must factor in sustainability and ethics. Good sourcing helps ensure that materials arrive on time and meet quality standards, which directly affects the overall success of the final product.

3. Manufacturing

The manufacturing phase is where raw materials are transformed into finished products. This step involves important activities like assembling different parts, testing the products to ensure quality, and packaging them properly for delivery. Engineers play an important role in this step by ensuring that machines are well-maintained and production lines run smoothly. Factories also schedule production runs, manage workers and machines, and label the products correctly. This stage plays a key role in the supply chain because it directly affects the quality and availability of products. If there are any delays or mistakes during manufacturing, it can cause problems throughout the entire supply chain. That’s why it’s important to keep this process smooth, accurate, and well-organised.

4. Delivering

How do products get from the warehouse to your doorstep so quickly? Fortunately, that’s where delivery comes in. Also known as the logistics stage, this step ensures finished products reach customers quickly, safely, and accurately. This step includes important activities like managing transportation, handling warehouse operations, processing customer orders, tracking shipments, and offering after-sales support. A smooth delivery process helps build trust and keeps customers happy. On the other hand, late or incorrect deliveries can lead to customer complaints, damage your brand’s reputation, and cause financial loss. That’s why effective delivery and distribution are essential parts of a successful supply chain.

5. Returning

Have you ever thought about what happens when a customer returns a product or a shipment gets damaged? Surprisingly, that’s where reverse logistics plays a key role in keeping the customer experience smooth. Reverse logistics is the process of handling returned products, which includes everything from restocking to repairing and recycling. This step includes managing returns and refunds, checking faulty or recalled items, and making sure products are recycled, reused, or safely disposed of. Moreover, effective reverse logistics helps businesses gain insights into product quality, allowing manufacturers to improve production processes and reduce defects. A smooth and simple return process helps build customer trust and loyalty.

Final Thoughts

Supply Chain Management is much more than just moving products from one place to another. It’s a complex system that requires coordination, foresight, and adaptability. Businesses can increase efficiency, reduce costs, and deliver greater value to their customers with the help of these five basic steps of supply chain management. Whether you’re studying supply chain management, running a business, or simply exploring a career in logistics, understanding these steps will provide a solid foundation to deal with the modern marketplace.